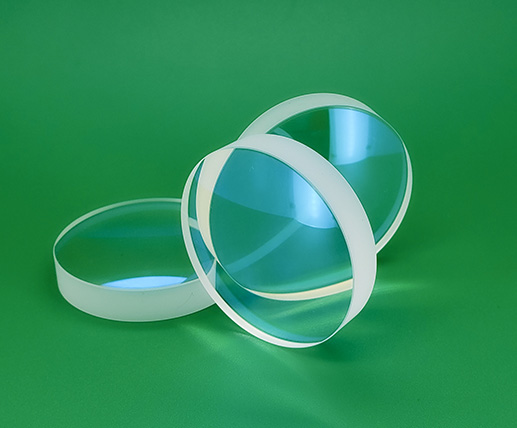

Longart's exquisite Glass Swimming Pool Mosaic is an unparalleled piece of Swimming Pool Mosaic Art that will transform any pool into a stunning work of art. Our mosaic art pieces are made with the finest quality glass and are designed to enhance the beauty of your swimming pool.

Our Glass Swimming Pool Mosaic Art is perfect for both residential and commercial swimming pools. Whether you want to create a serene and peaceful environment or a fun and playful atmosphere, our mosaics can help you achieve your desired look. The unique design of the mosaic tiles creates a mesmerizing visual effect, which will add an element of elegance and sophistication to any swimming pool.

Our Glass Swimming Pool Mosaic is available in a wide range of colors, patterns, and sizes, giving you the flexibility to choose the perfect design that suits your style and preferences. Our team of experienced craftsmen can also create custom designs, ensuring that your pool mosaic is truly one-of-a-kind.

Not only is our Glass Swimming Pool Mosaic visually appealing, but it is also highly durable and resistant to fading, chipping, and discoloration, making it a long-lasting investment for your pool.

Longart's Glass Swimming Pool Mosaic offers a unique blend of aesthetics, durability, customizability, functionality, and ease of installation, making it the perfect addition to any swimming pool, here's an introduction to Longart's Glass Swimming Pool Mosaic from different perspectives:

①Aesthetics: Longart's Glass Swimming Pool Mosaic is a stunning work of art that will add a touch of elegance and sophistication to any swimming pool. The unique design of the mosaic tiles creates a mesmerizing visual effect, which will captivate the attention of anyone who sets their eyes on it.

②Durability: Longart's Glass Swimming Pool Mosaic is crafted with the finest quality glass, making it highly durable and resistant to fading, chipping, and discoloration. This ensures that your pool mosaic will remain as beautiful and vibrant as the day it was installed for years to come.

③Customizability: Longart's Glass Swimming Pool Mosaic is available in a wide range of colors, patterns, and sizes, giving you the flexibility to choose the perfect design that suits your style and preferences. Our team of experienced craftsmen can also create custom designs, ensuring that your pool mosaic is truly one-of-a-kind.

④Functionality: Longart's Glass Swimming Pool Mosaic not only looks great, but it also serves a practical purpose. The mosaic tiles are slip-resistant, providing a safer surface for swimmers to walk on. Additionally, the tiles are easy to clean and maintain, making them a practical choice for any pool owner.

⑤Installation: Installing Longart's Glass Swimming Pool Mosaic is an easy process, and our team of experts will work with you every step of the way to ensure a seamless installation experience. We use only the highest quality materials and techniques to ensure that your pool mosaic is installed to the highest standard.

Longart's Glass Swimming Pool Mosaic is the perfect addition to any pool, offering a unique blend of beauty, durability, and functionality. Trust us to create a breathtaking masterpiece that you will enjoy for years to come.

Installing our Swimming Pool Mosaic Art is an easy process, and our team of experts will work with you every step of the way to ensure a seamless installation experience.

Investing in our Glass Swimming Pool Mosaic Art is an investment in the beauty and longevity of your swimming pool. Contact us today to learn more about our products and how we can help you create the swimming pool of your dreams.