Optical lenses play a crucial role in various fields, from photography to ophthalmology. They manipulate the path of light, allowing us to focus images and correct vision. Among the diverse types of lenses, two primary categories stand out: concave and convex lenses. In this comprehensive guide, we delve into the intricacies of these lenses, elucidating their differences and applications.

Definition and Structure

Concave Lens

A concave lens, also known as a diverging lens, possesses a curved surface that bulges inward. This curvature causes light rays passing through it to diverge or spread out. The center of a concave lens is thinner than the edges, giving it a distinctive indented appearance.

Convex Lens

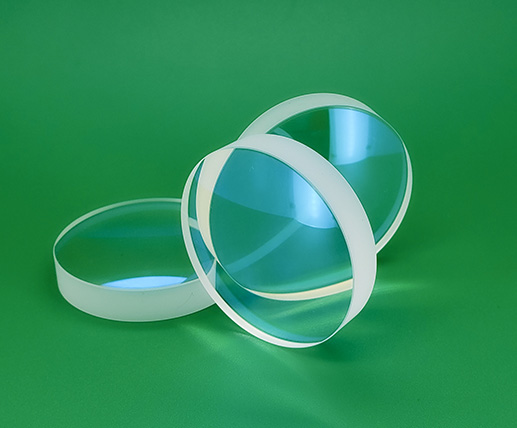

Conversely, a convex lens, termed a converging lens, features a curved surface that bulges outward. Light rays passing through this lens converge or focus to a point on the opposite side. The center of a convex lens is thicker than the edges, resulting in a rounded, protruding shape.

Optical Properties

Concave Lens

Divergence: Concave lenses cause incident light rays to diverge upon passing through them.

Virtual Image Formation: When light rays diverge, they appear to originate from a point behind the lens, forming a virtual image.

Corrective Vision: In ophthalmic applications, concave lenses are utilized to correct myopia (nearsightedness) by diverging light before it reaches the eye's lens.

Convex Lens

Convergence: Convex lenses converge incident light rays to a focal point beyond the lens.

Real Image Formation: As light rays converge, they intersect at a point, forming a real image on the opposite side of the lens.

Vision Correction: Convex lenses are employed to correct hyperopia (farsightedness) by converging light onto the retina, compensating for the shorter focal length of the eye.

Applications in Optics and Beyond

Concave Lens

Camera Lenses: Concave lenses are utilized in cameras to widen the field of view and correct distortions.

Galilean Telescopes: The eyepiece of Galilean telescopes often incorporates a concave lens to produce a virtual image for the observer.

Diving Masks: Some diving masks integrate concave lenses to compensate for the underwater magnification effect, providing a clearer view.

Convex Lens

Photography: Convex lenses are fundamental components of camera lenses, focusing light onto the camera sensor to capture images.

Magnifying Glasses: The convex shape of magnifying glasses enables them to magnify objects by converging light rays, facilitating detailed examination.

Projectors: Projector systems employ convex lenses to converge light from the source onto a screen, producing enlarged images for viewing.

Conclusion

In summary, the disparity between concave and convex lenses lies in their optical properties and applications. While concave lenses diverge light, convex lenses converge it, leading to distinct image formations and corrective functions. Understanding these differences is crucial in selecting the appropriate lens for a myriad of optical and visual tasks.